Image set

Related services

Opening article section

Article section

Lead

Rich text

Stéphanie Blanchard, Englobe’s Technical Director, Soil and Materials Engineering in Quebec, provides an overview of innovation when it comes to the investigation of reinforced concrete structures – just one aspect of the vast expertise her team offers customers, both in the public and private sector.

As many reinforced concrete structures in the province are aging and increasingly stressed, the evaluation and diagnosis of concrete structures must be part of the inspection and maintenance program of any structural asset’s owner.

Englobe boasts a team of experts who are adept at identifying the causes of deterioration and in developing different investigation methods to locate and quantify the extent of the damage. The identification of degradations and the extent of the damage are the basis for the success of the repair work.

Rich text

What does a reinforced concrete assessment campaign consist of?

1. Structure documentation study

During an assessment campaign, our experts make sure to follow a series of steps starting with a study of the documentation on the structure. This consists of gathering all available information on the design, construction, use and maintenance of the structure.

Article quote

Rich text

2. Service condition analysis

The concrete structures assessment campaign validates if the original specifications still meet the current function. This step is of crucial importance since it is usually responsible for identifying the main causes of degradation. Our experts must then focus on several aspects, namely, the parts of the structure that are the most stressed – those exposed to freeze-thaw cycles, thermal cycles and humidity variations.

Article quote

Rich text

3. Site visit and mapping of damages

After analyzing the various service conditions, a site visit must be performed to carry out a visual examination and hammer sounding of the surfaces of the concrete structure. This is a rather simple operation that consists of noting:

- the size of the parts, the location and type of degradation (cracks, delamination, spalling, etc.)

- the characteristics of the degradation (opening, length, width, etc.)

- the location of the elements embedded in the concrete (reinforcement, strands, etc.).

At this stage, the various degradations and repair areas can be mapped out.

4. On site non-destructive evaluation and laboratory testing

A detailed evaluation program of the concrete structure or element is then determined and carried out. This includes non-destructive evaluation methods and laboratory tests at targeted locations to confirm or refute the causes of degradation.

5. Detailed report

Englobe’s specialized engineers gather the conclusions of the investigation in a report that identifies in detail the localization and causes of degradation as well as the extent to which the structure is damaged. This report also includes a corrective action plan categorizing the actions to undertake by priority.

Content

Statistic carousel

Statistic

Statistic

Article section

Rich text

OUR TOP 3 INNOVATIVE NON-DESTRUCTIVE EVALUATION TECHNOLOGIES

While setting the record straight to plan the maintenance program of any structural asset is key, we know that preserving the infrastructure’s condition while assessing it, is crucial. Here are some of our top non-destructive evaluation technologies we use depending on the infrastructure composition, condition and localization.

1. The electromagnetic wave propagation method

Our teams of experts use a radar machine to send electromagnetic waves through the structure. These waves are the result of the coupled vibration of an electric field and a magnetic field that vary in time and can undergo reflection or refraction. In reflection, the wave returns to where it came from, while in refraction, the wave continues along its path through the second medium and changes direction.

Did you know? The wetter a material is, the slower the propagation speed. In fact, the speed of propagation of the wave depends on the dielectric constant of the medium, as well as the electrical permittivity (εr) and electrical conductivity (σ).

Media

Image set

Rich text

2. The acoustic wave propagation method

Several methods exploit this technique, however, the most commonly used techniques are impact-echo (IE), pulse-echo and ultrasonic vibration. When an acoustic wave propagates through a non-homogeneous medium, it will undergo diffraction at the impurities it encounters or at the interfaces between layers of different materials. These results help us determine the condition of the structure.

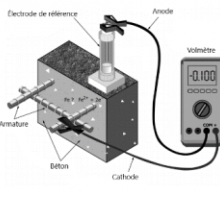

3. The electrical potential, or corrosion potential method

The non-destructive evaluation method by electrical potential, or corrosion potential, is a technique commonly used in the evaluation of structures in Quebec and elsewhere in the world. While limited to uncoated carbon steels and concrete coatings structures, this method can be used on a large scale to identify areas susceptible to corroded reinforcement and delamination.

Reinforced concrete assessment is a powerful decision-making tool. Make sure to contact us to plan your maintenance program and get the most out of your asset!

Media

Image set